Rust never sleeps is the cliché of corrosion. Rust is a destroyer and a product of corrosion. Corrosion can be accelerated by the presence of hydrogen sulfide, generated by biologic activity in pipelines as wastewater is pumped. The presence of hydrogen sulfide causes biogenic corrosion, driven by naturally occurring bacteria that produce sulfuric acid. Sulfuric acid can cause pitting corrosion in steel and damage anything in contact including concrete and steel used in pipelines and wastewater treatment equipment, including the headworks of a treatment plant.

A few best practices can be used for corrosion control of preliminary equipment, including material selection, passivation, assembly control, and ISO certified process control.

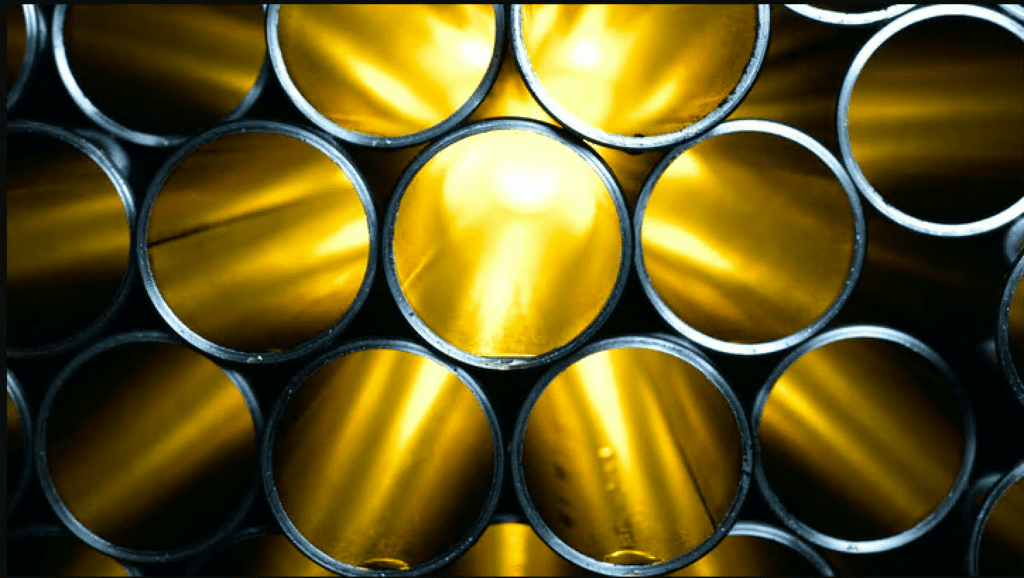

Corrosion control starts with using the right materials. Headworks equipment materials must be acid resistant to withstand biogenic corrosion and strong to stand up to hydraulic forces. Stainless steel is an excellent material that meets these requirements.

The passivation of stainless steel is another practice that is critical to maintain corrosion control. ASTM standard A380 provides guidelines to passivate stainless steel. Stainless must first be thoroughly cleaned to provide a surface free of dirt, grease, or oil. Hydrofluoric acid is used to remove scale that forms around welded areas. Contact with nitric acid is used to passivate the surface with a protective layer. Total immersion in an acid solution has proven to produce a good quality passivated stainless surface. Other passivation methods are not as precise in providing the contact time at proper concentration and should be avoided.

The protective chromium oxide layer prevents the stainless from corroding but is very thin requiring specialized testing to measure and can be damaged. Once the protective layer is formed, no iron tools should contact the passivated surface. Cutting and grinding on or near passivated these surfaces should be minimized or eliminated.

ISO 9001 is a key practice in keeping quality of processes needed for long-term corrosion control. ISO provides a framework to certify product quality. An equipment purchaser should consider requiring ISO certification from a supplier with full control of manufacturing. A manufacturer that has full control of all processes under one roof is in the best position to control the quality of the equipment through design, fabrication, passivation, assembly, and testing. If key processes are outsourced, guarantees should be required ensuring component quality is controlled by naming subcontractors and their ISO certifications.

Preliminary treatment equipment lives in the toughest part of the treatment train and therefore should have the most quality control through selection and procurement. All manufacturing processes, especially passivation and assembly, should be vetted. Vetting includes visiting the manufacturer to understand the processes used and to ensure corrosion control practices are followed. Rust may never sleep, but corrosion can be put to bed even in the worst environments with correct key practices. WW

About the Author: Jay R. Conroy is founder and president of Hydro-Dyne Engineering Inc. He is also a member of the Water and Wastewater Equipment Manufacturers Association (WWEMA) Board of Directors and serves as Chair of the Marketing and Member Services Committee. WWEMA is a non-profit trade association formed in 1908 to represent water and wastewater technology manufacturers and related service providers. WWEMA is made up of many of the most prominent and influential companies in the industry who are working together to shape the future of water and wastewater technology in the U.S. and around the world. For more information about WWEMA, go to www.wwema.org. Interested in becoming a WWEMA member? Contact WWEMA Executive Director Vanessa Leiby at vanessa@wwema.org.

/NQA-ISO-9001-Logo-ANAB.jpg)