A poorly functioning wastewater screening system will lead to higher maintenance costs – and possibly catastrophic results for your facility and those it serves. Even if you avoid a total shutdown, those costs can eat significantly into your overall facility budget and cause your operations to be expensively inefficient. When equipment fails because you have an inadequate system, the downtime compromises your mission. But all of that is avoidable.

We’ve created an infographic to help you take an expert approach to your plant’s headworks. You’ll learn about the criteria that affect proper screen design and what steps you should take to maintain your screening equipment.

In the full infographic, we address these and more factors to be aware of and respond to, including changes to the processes in your plant, growth of the community you serve, and regulatory requirements.

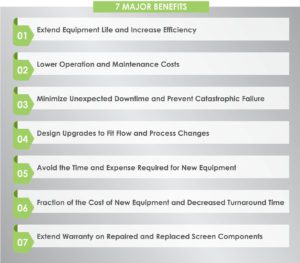

When you work with Hydro-Dyne to remanufacture your screening equipment, you will:

When you work with Hydro-Dyne to remanufacture your screening equipment, you will:

Learn more about our proven remanufacturing process and how it can maximize the life of your screening equipment.

Download our infographic “Is It Time to Rebuild Your Screening Equipment” and use it as a guide to assess the state of your headworks.

If you’re not sure if you need to rebuild, Hydro-Dyne can help evaluating current condition of your equipment components.

To speak with a Hydro-Dyne expert about your operations and whether remanufacturing your headworks is right for you, call us at 813-818-0777. We look forward to bringing your equipment back to like-new condition.

4750 118th Avenue North Clearwater, Florida 33762 USA Phone: +1 (813) 818-0777 Fax: (813) 818-0770

Copyright ©2025 Hydro-Dyne Engineering. All Rights Reserved. | Privacy Policy | Terms of Use