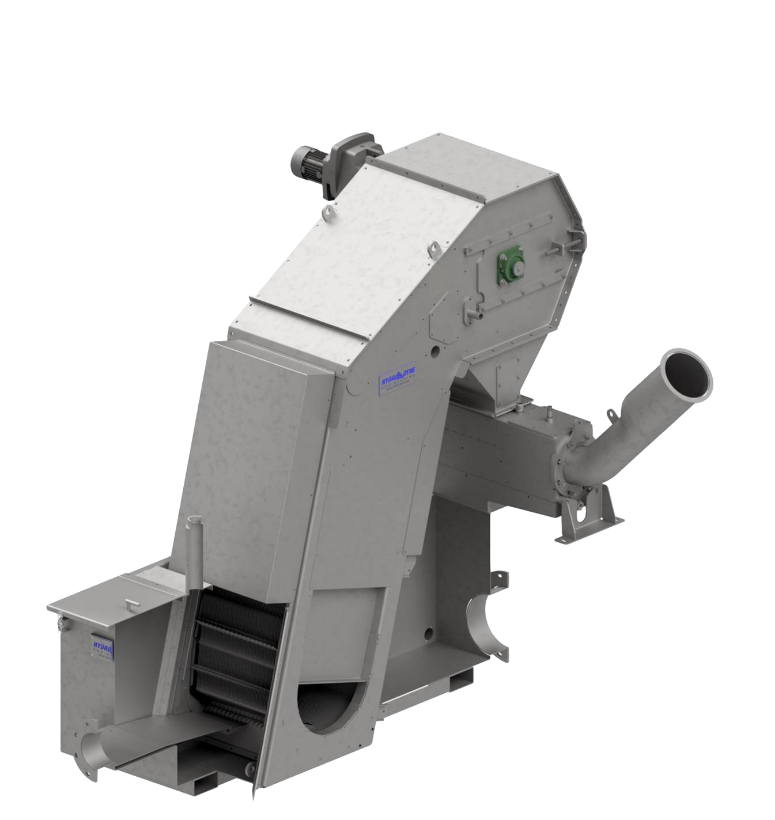

In our previous post, we looked at the role that center flow and drums screens play in supporting MBR systems in wastewater treatment facilities. Now, we’d like to focus on the lessons we at Hydro-Dyne have learned over years of retrofitting other screening systems. Below, we share the knowledge we’ve gained from designing new systems for a variety of plants (MBR or otherwise).

4 Lessons Learned from Working with Membrane Bioreactor Systems