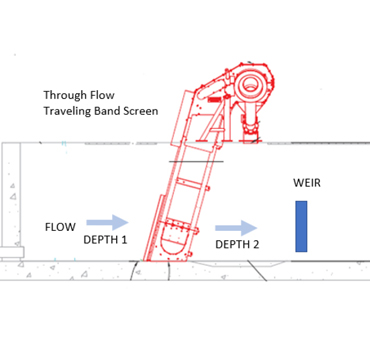

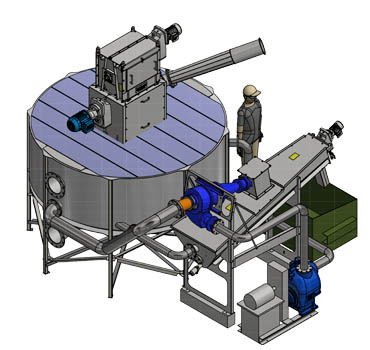

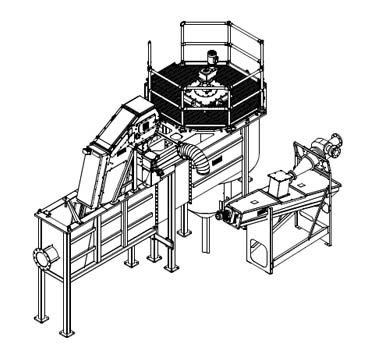

Best Practices for Wastewater Screening Design The Use of Weirs to Optimize Screen Design Wastewater screening is the crucial first step in the wastewater treatment process, designed to remove large solid materials and debris from the influent wastewater. This process is essential to safeguard downstream treatment units and prevent potential equipment damage, operational inefficiencies, and… Continue reading Guide to Wastewater Screening Design

Guide to Wastewater Screening Design